- Home

- >

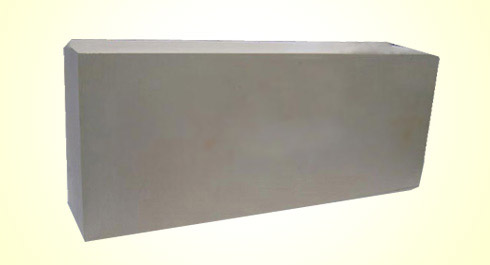

- Products > Fused Cast AZS Block >

For more Information of the Product ,Please

Feature

▶ Features:

◆ Strong glass corrosion resistance and high thermal shack stability.

◆ Good RUL, wear-resistance, dregs-resistance and alkali corrosion resistance.

◆ The products are adopting superior material, with process by special arc furnace forming it. This fused cast technology got nearly no suffer from electrode pollution.

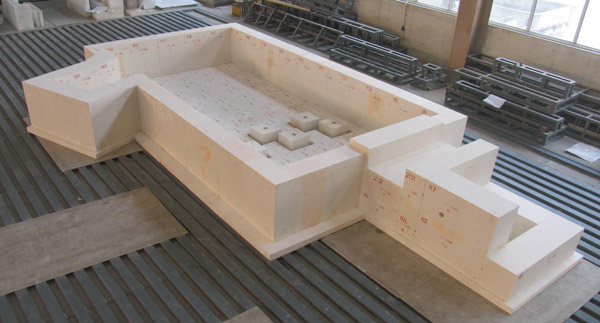

▶ Application:

According to above,they can be used at parts where chemical erosion is serious and temperature changes frequently, can be widely used in the lining of glass furnace,the chemical industrials,metallurgical furnace.

Technical Data

| Item | Behaviors | |

| TY-AZS36 | ||

| Chemical Composition | Al2O3 | ≥49.00 |

| ZrO2 | ≥35.50 | |

| SiO2 | ≤13.50 | |

| Na2O+K2O | ≤1.35 | |

| Bulk density (g/cm3) | ≥3.85 | |

| Apparent Porosity (%) | ≤1.0 | |

| Cold Crushing Strength (Mpa) | ≥300 | |

| Exudation Temperature of Glass Phase | ≥1400 | |

| Bubble Separation Ratio (1300℃×10h) | ≤1.4 | |

| Anti-corrosion rate of glass liquid 1500℃×36h (mm/24h)% | ≤1.3 | |

| Apparent density (g/cm3) | PT(RN RC N) | ≥3.50 |

| ZWS(RR EVF EC ENC) | ≥3.70 | |

| WS( RT VF EPIC FVP DCL) | ≥3.80 | |

Inquiry

For more information on any of our products please get in touch using the form below. One of our sales team will respond to your enquiry as soon as possible.

Copyright © 2014 Zhengzhou Sunrise Refractory Co., Ltd. Site Index Product Index