Product List

Success Case

Contact Us

- 0086 371 63838939

- 0086 371 63835539

- sales@sunriserefr.com

- tkfanyi

- No.36 Fengchan Road, Zhengzhou City

News

Introduction of refractory corundum brick

- More related products

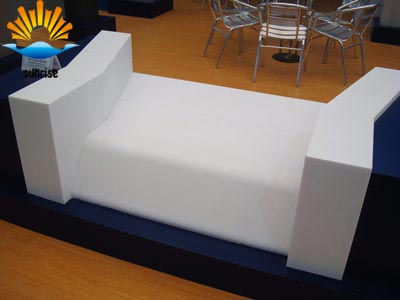

- Fused Cast AZS Block

- Fused Cast Alumina Block

- Fused Cast High Zirconia Block

- Fused Cast Skid Rail Block

- Read more

Leave Message

For more information on any of our products please get in touch using the form below. One of our sales team will respond to your enquiry as soon as possible.

Copyright © 2014 Zhengzhou Sunrise Refractory Co., Ltd. Site Index Product Index