Product List

Success Case

Contact Us

- 0086 371 63838939

- 0086 371 63835539

- sales@sunriserefr.com

- tkfanyi

- No.36 Fengchan Road, Zhengzhou City

News

Refractory Materials Used In the Regenerator of the Hot Blast Stove

- More related products

- Fused Cast AZS Block

- Fused Cast Alumina Block

- Fused Cast High Zirconia Block

- Fused Cast Skid Rail Block

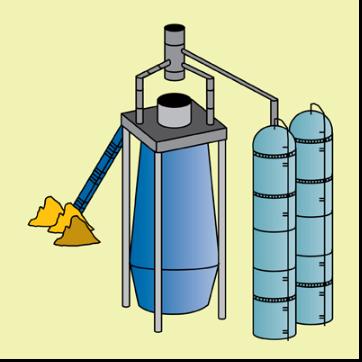

Regenerator is the main location of the heat exchange of hot blast stoves. It is a checker chamber constructed with checker bricks, a huge checker brick stack.

1) The middle and low temperature zone

In the low temperature zone, the temperature is not more than 900℃. It is mainly used to bear the gravity load of the upper masonry and strong convective heat exchange in the initial blowing stage. So, cheap fire clay brick with good thermal shock resistance is enough to meet the requirements.

The temperature in the central region of the regenerator temperature often fluctuates in the 800-1100℃. This is the transition zone between high temperature zone and the low temperature zone. The refractory products not only have to bear the gravity load of upper bricks and the temperature fluctuation during the transformation process of air blowing and combustion, but also bear a certain high temperature. Therefore, high-temperature creep performance is particularly important. Generally low creep fire clay brick or low creep high alumina brick with good creep resistance is used.

2) High temperature zone

In the upper part of the regenerator, since the temperature is high and alternately changed, the refractory materials are required to have good thermal stability. High alumina brick, due to its creep and expansion characteristics, cannot be used in this area.

Andalusite brick has high refractoriness and softening temperature under load and good thermal stability and thermal shock resistance. It can be used in this area, but it is expansive.

In recent years, since silica brick has good expansion characteristics and high softening temperature under load (1640-1680℃, close to the melting point of tridymite and cristobalite (1470 ℃ and 1713 ℃)), it is more and more widely used in replacement of high alumina refractory materials. However, silica brick is easy to spall at 900℃. Tridymite, cristobalite and residual quartz in the silica brick all have two variants, reconstructive type and displacement type. The variants have huge expansion and shrinkage with the change of the temperature. Due to this, heating and cooling must be in strict accordance with the prescribed manner. In addition, since the density of silica brick is lower, its heat storage capacity is therefore lower.

The selection of the height of the silica layer is not the same. When determining the height, various factors should be taken into consideration. If silica brick is used in the high temperature zone, compatible light weight silica insulation brick is used in the insulation layer.

- Read more

Leave Message

For more information on any of our products please get in touch using the form below. One of our sales team will respond to your enquiry as soon as possible.

Copyright © 2014 Zhengzhou Sunrise Refractory Co., Ltd. Site Index Product Index