- 0086 371 63838939

- 0086 371 63835539

- sales@sunriserefr.com

- tkfanyi

- No.36 Fengchan Road, Zhengzhou City

News

Casting Technology Of Fused Cast AZS Blocks For Glass Industry

- More related products

- Fused Cast AZS Block

- Fused Cast Alumina Block

- Fused Cast High Zirconia Block

- Fused Cast Skid Rail Block

Casting is a 6000 year old process which is widely applied to many industries, such as metal, plastic and resign,in addition, casting is also used in glass industry. Casting method is applied to produce fire bricks which is used in the glass furnace. As this method can produce bricks which have less shrinkages, high density, long using life, high temperature resistance and strong anti-corrosion to galss liquid. So casting is widely used in producing glass.

Casting manufacturing process is that by melting the material into liquid, and then pouring the liquid material into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify, then through cleaning and inspection. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process. Casting materials are usually metals or various cold setting materials that cure after mixing two or more components together; examples are epoxy, concrete, plaster and clay. Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods.

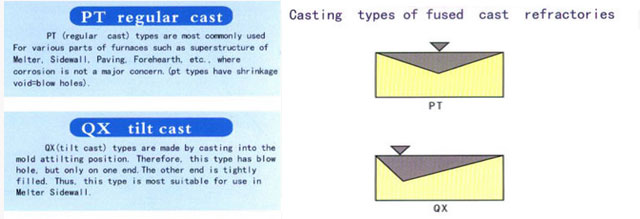

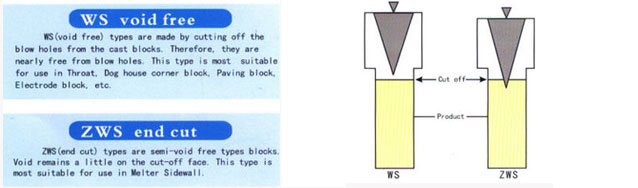

According to the quantity of shrinkages, casting can be divided into below four styles:

1.PT-normal casting, the shrinkage voids of brick are formed under the casting scar.

2.QX-tilt casting, the shrinkage voids of brick are located at the rear bottom side, and a complete dense zone forms at the opposite end.

3.ZWS-end casting, this casting method is similar with WS, merely a few shrinkage voids remain in upper part of the body.

4.WS-void free casting, the zone where the shrinkage voids located is cut off, no shrinkage voids left in brick.

Leave Message