Product List

Success Case

Contact Us

- 0086 371 63838939

- 0086 371 63835539

- sales@sunriserefr.com

- tkfanyi

- No.36 Fengchan Road, Zhengzhou City

News

The Different Applications Of Fused Cast AZS Block 33# 36# 41#

- More related products

- Fused Cast AZS Block

- Fused Cast Alumina Block

- Fused Cast High Zirconia Block

- Fused Cast Skid Rail Block

Fused Cast AZS Block is also called electro Zircon corundum block which is abbreviated as AZS because it contains the chemical composition of Al2O3-ZrO2-SiO2. A is from Al2O3, Z is from ZrO2 and S is from SiO2. According to the different content of Zirconia from 33%-41%, fused cast AZS block can be divided into three types AZS33#,AZS36# and AZS41#. Fused cast AZS block 33# 36# 41# is made from pure alumina powder and Zircon sand (composed of 65% zirconia and 34% SiO2). After Alumina powder and zircon sand melting in electric furnace, they are casted into various molds and cool themselves down to become white solid.

All of fused cast AZS block 33#,36# and 41# as refractory bricks have the common properties of dense structure, withstanding high temperature, low pollution to glass liquid, high corrosion resistance to glass liquid, and specific chemical composition. However, as the different content of zirconia, fused cast AZS block 33#, 36# and 41# can be used in different part of glass furnace.

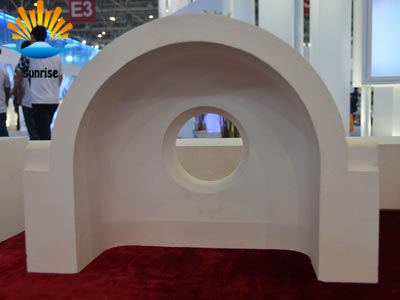

Fused cast AZS block 33#: It has the good casting property which shows that it can be made many kinds of formats and shapes. Fused cast AZS block 33# is mainly used in relatively low temperature and corrosive parts of glass furnace such as working ends, feeder channel, etc.

Fused cast AZS block 36#: It has lower casting property compared to fused cast azs block 33#, so fused cast AZS block 36# is only available for straight brick and it is recommended to be used in sections where corrosion and temperature is higher, such as sidewall, paving, doghouse, etc.

Fused cast AZS block 41#: This block is available in a large size straight or approximates block and special formats and shapes for glass furnace. Fused cast AZS block 41# is especially applied to seriously corrosive parts of glass furnace such as throat, bottom budding, dam block, electric block corners, doghouse and also can be used in sidewalls.

Thanks for your visiting! If you are interested in our products or have any question, please don't hesitate to contact us for further information.

| Item | TY-AZS33 | TY-AZS36 | TY-AZS41 | |

| Chemical Composition | Al2O3 | ≥50.00 | ≥49.00 | ≥45.00 |

| ZrO2 | ≥32.50 | ≥35.50 | ≥40.50 | |

| SiO2 | ≤15.50 | ≤13.50 | ≤13.00 | |

| Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

| Volume density g/cm3 | ≥3.75 | ≥3.85 | ≥4.00 | |

| Apparent Porosity % | ≤1.2 | ≤1.0 | ≤1.2 | |

| Cold Crushing Strength Mpa |

≥300 | ≥300 | ≥300 | |

| Exudation Temperature of Glass Phase |

≥1400 | ≥1400 | ≥1400 | |

| Bubble Separation Ratio(1300℃×10h) |

≤1.2 | ≤1.0 | ≤1.0 | |

| Anti-corrosion rate of glass liquid 1500℃×36h (mm/24h)% |

≤1.4 | ≤1.3 | ≤1.2 | |

| Bulk density(g/cm3) | PT | ≥3.50 | ≥3.50 | ≥3.70 |

| ZWS | ≥3.65 | ≥3.75 | ≥3.90 | |

| QX | ≥3.65 | ≥3.75 | ≥3.90 | |

| WS | ≥3.75 | ≥3.85 | ≥4.00 | |

Leave Message

For more information on any of our products please get in touch using the form below. One of our sales team will respond to your enquiry as soon as possible.

Copyright © 2014 Zhengzhou Sunrise Refractory Co., Ltd. Site Index Product Index