Product List

Success Case

Contact Us

- 0086 371 63838939

- 0086 371 63835539

- sales@sunriserefr.com

- tkfanyi

- No.36 Fengchan Road, Zhengzhou City

News

Fused Cast AZS Block Applying To The Flame Position

- More related products

- Fused Cast AZS Block

- Fused Cast Alumina Block

- Fused Cast High Zirconia Block

- Fused Cast Skid Rail Block

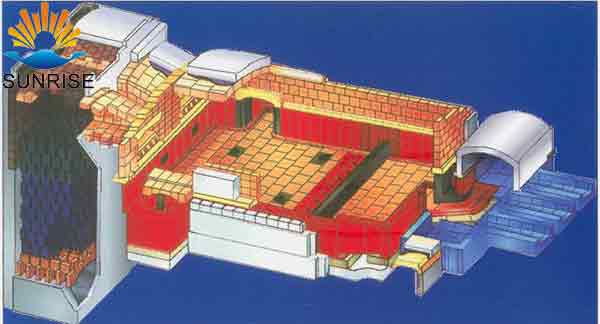

As everyone knows, the position which is contacted with flame in glass furnace is quite important, so how to choose refractory bricks of this part?

1. Furnace roof and breast brick

Furnace arch space adopts 70mm insulation coating, 134mm lightweight silica brick, 30mm silica sealing material, 450mm high quality silica brick; internal of breast wall uses fused cast AZS block 33# and the external uses insulation brick.

2. Front wall brick

The front wall currently adopts fused cast AZS block 33# or sintered AZS brick, and there will be putting high quality silica brick and sintered AZS brick into compound use. Generally, the top uses high quality silica brick, and the bottom uses fused cast AZS block 33#.

3. The port brick

The port of glass furnace mainly contains crater arch, furnace arch oblique head layer, bottom floor of port, tongue crown of port and nozzle brick which all adopt fused cast AZS block. Insulation brick of top crown of port uses lightweight fire clay insulation brick.

4. Internal side around regenerator chamber

High quality silica brick is used, and the bottom uses low porosity fire clay brick, the lowest part uses ordinary clay brick, the top crown of upper regenerator chamber adopts high quality silica brick with lightweight fire clay bricks as the insulation bricks, the bottom arch bar adopts low porosity fire clay brick.

Leave Message

For more information on any of our products please get in touch using the form below. One of our sales team will respond to your enquiry as soon as possible.

Copyright © 2014 Zhengzhou Sunrise Refractory Co., Ltd. Site Index Product Index